High Pressure Triplex Plunger Pump

Our high-pressure triplex plunger pumps are built to deliver strong and steady performance for tough jobs that need high pressure, offering unmatched reliability and consistent output even in the harshest conditions. These pumps are perfect for industries like oil and gas, water jetting, and pressure washing, where powerful fluid delivery is essential. Their ability to handle various types of fluids makes them versatile for many applications.

The triplex design ensures smooth operation and less vibration, while the strong build makes these pumps durable and reliable in tough conditions. These pumps are made to be efficient, using less energy while providing high performance. With simple maintenance and long-lasting parts, our high-pressure triplex plunger pumps are a cost-effective and dependable solution for your pumping needs.

Download High Pressure Triplex Plunger Pump Catalogue

Applications

- Chemical Injection

- Hydro Jetting and Cutting

- Cement Grouting

- Detergent Slurry

- Hydrostatic Testing

- Salt Water Injection

- Boiler Feed

- Reverse Osmosis

- Mechanical Separation

- Process Water Disposal

- Ammonia Scrubber … & many other applications

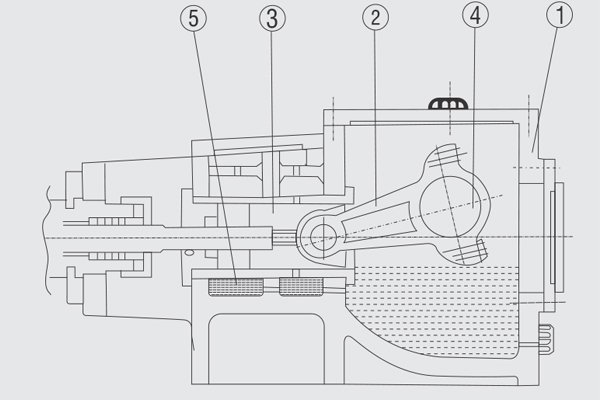

Power End

For each Ronak Pumps, the POWER END is engineered out of selected materials and it is designed for the rated horsepower.

1. CRANK CASE

The crank case is of sturdy design, completely sealed and made out of C.I.

2. CONNECTING ROAD

Accurately machined, self lubricated connecting road are machine out of the high grade material.

3. CROSS HEAD

Large, full piston type Crosshead ensures accurate plunger alignment and also minimizes side thrust.

4. CRANK SHAFT

Heavy duty accurately machined crank shaft is made out of alloy steel with hardening and grinding.

5. LUBRICATION

Unique design ensure combined pressure lubrication which provides on crank shaft & cross-heads.

High quality tapper roller bearings are used. internal, to provide support to the crank shaft – at both ends.

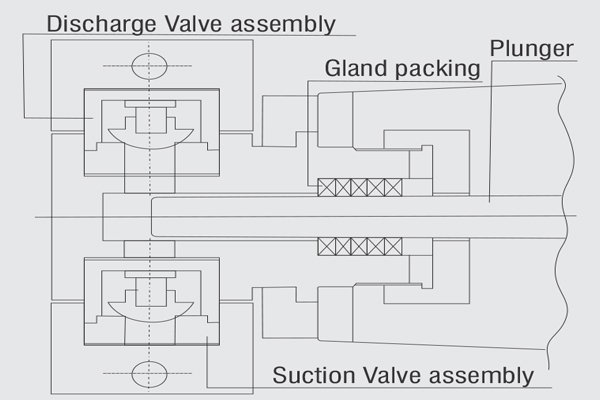

Liquid End

For each Ronak Pump the LIQUID END is painstakingly crafted. RPVPL also offer liquid ends which are tailor made out of a variety of corrosion and fatigue resistant materials exactly confirming to a customer’s particular needs.

NOTES :

Parts consisting of special materials. such as alloy 20, monel, hastealloys etcetra can be specially manufactured against specific needs.

Facilities are available to supply ceramic coated or hardchrome plated or nitrided plungers. Gland packing, flushing. cooling lubricaiton can also be provided against specific orders

Triplex Metering Plunger Pump is also available.

Capacity Section Chart

| Model | Plunger Diameter | Discharge Pressure | Flow Rate In LPM At Standard Stroke Per Minute | ||||

| MRPHPTP – 2500

MRPHPTP – 4000

MRPHPTP – 5000

MRPHPTP – 7000

MRPHPTP – 10000

MRPHPTP – 20000 |

(mm) | (kg/cm²) | 100 | 150 | 200 | 300 | 400 |

| 10 | 700 | 0.60 | 0.89 | 1.27 | 1.90 | 2.60 | |

| 15 | 340 | 1.45 | 2.15 | 2.90 | 4.30 | 5.80 | |

| 20 | 105 | 2.50 | 3.75 | 5.00 | 7.50 | 10.00 | |

| 25 | 125 | 4.00 | 6.00 | 8.00 | 12.00 | 16.00 | |

| 30 | 100 | 5.30 | 8.00 | 10.70 | 16.15 | 21.53 | |

| 20 | 350 | 3.5 | 5.00 | 7.00 | 10.00 | 13.00 | |

| 25 | 220 | 5.0 | 8.00 | 10.00 | 16.00 | 21.00 | |

| 30 | 150 | 7.5 | 11.00 | 15.00 | 22.00 | 30.00 | |

| 35 | 110 | 10.5 | 15.50 | 21.00 | 31.00 | 42.00 | |

| 40 | 85 | 13.5 | 20.00 | 27.00 | 40.00 | 54.00 | |

| 25 | 440 | 7.0 | 11.00 | 14.00 | 22.00 | 29.00 | |

| 30 | 300 | 10.5 | 15.50 | 21.00 | 31.00 | 42.00 | |

| 40 | 170 | 18.5 | 27.50 | 37.00 | 55.00 | 74.00 | |

| 50 | 100 | 29.00 | 43.50 | 58.00 | 87.00 | 116.00 | |

| 55 | 90 | 35.5 | 53.00 | 71.00 | 106.00 | 142.00 | |

| 30 | 500 | 13.0 | 20.00 | 26.00 | 40.00 | 53.00 | |

| 40 | 270 | 23.5 | 35.50 | 47.00 | 71.00 | 95.00 | |

| 50 | 180 | 37.00 | 55.50 | 74.00 | 111.00 | 148.00 | |

| 55 | 150 | 45.00 | 67.50 | 90.00 | 135.00 | 180.00 | |

| 60 | 120 | 53.00 | 79.00 | 106.00 | 158.00 | 212.00 | |

| 50 | 300 | 53.00 | 79.00 | 106.00 | 158.00 | 212.00 | |

| 60 | 235 | 76.00 | 114.00 | 152.00 | 228.00 | 304.00 | |

| 65 | 198 | 90.00 | 135.00 | 180.00 | 270.00 | 360.00 | |

| 70 | 170 | 103.50 | 155.00 | 207.00 | 310.00 | 414.00 | |

| 75 | 150 | 119.00 | 178.50 | 238.00 | 357.00 | 476.00 | |

| 80 | 132 | 135.00 | 202.50 | 270.00 | 405.00 | 540.00 | |

| 62 | 200 | 162.00 | 243.00 | 325.00 | – | – | |

| 82 | 180 | 316.00 | 474.00 | 633.00 | – | – | |

| 102 | 160 | 440.00 | 660.00 | 880.00 | – | – | |

| 120 | 150 | 610.00 | 915.00 | 1220.00 | – | – | |