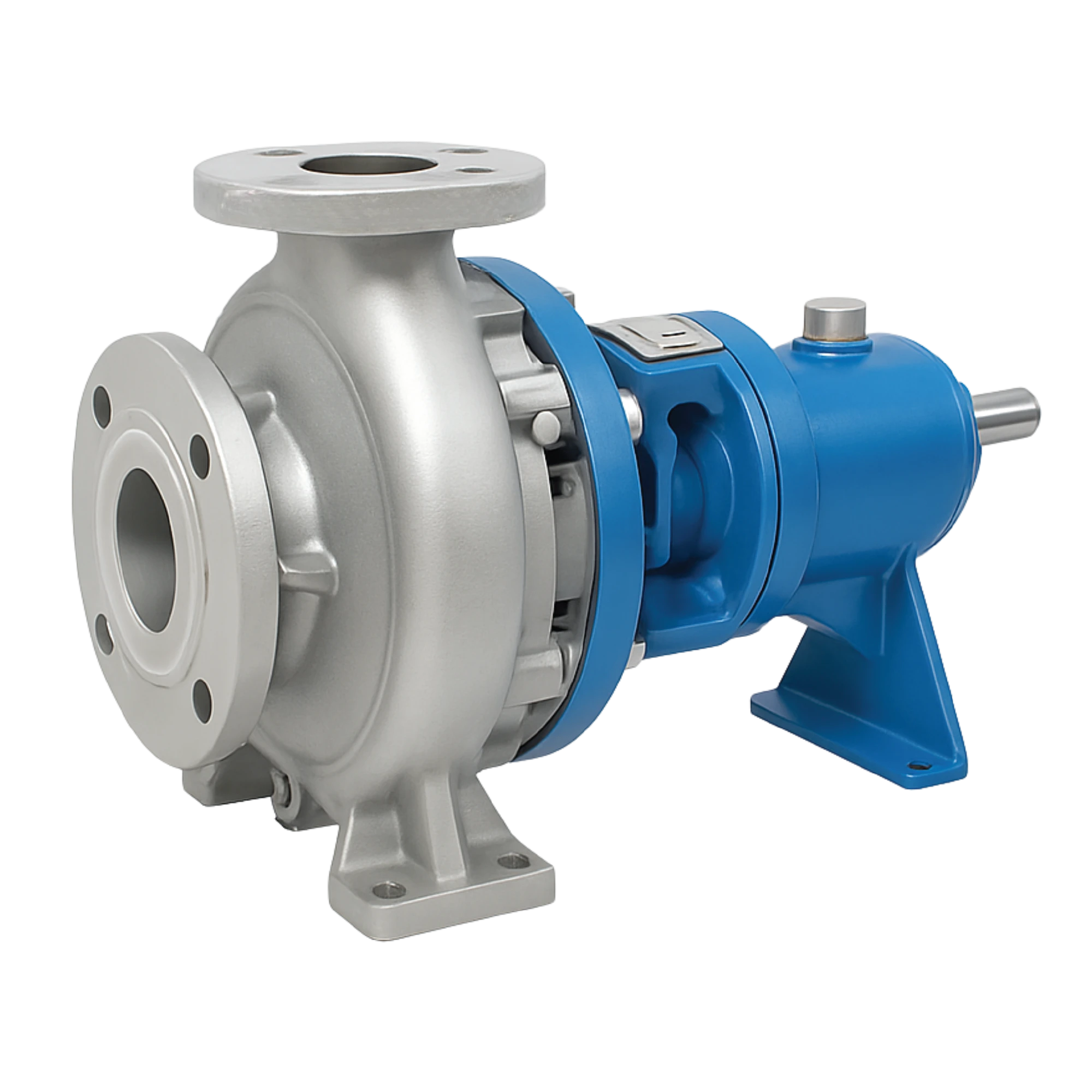

MRP Pumps delivers high-performance centrifugal pumps engineered for reliable operation across multiple industrial sectors. Our pumps excel in transferring various liquids – from clean water to corrosive chemicals and abrasive slurries – while maintaining consistent performance under demanding conditions.

These pumps feature innovative sealing technology and optimized bearing systems that enhance durability while reducing service intervals. Ideal for water management, chemical processing, petrochemicals, and food & beverage industries, our centrifugal pumps provide an economical solution for fluid handling challenges. Versatile mounting configurations allow seamless integration into existing or new installations.

Get Reliable Centrifugal Pumps – Fast & Customized

Download Our Centrifugal Pumps Catalogue

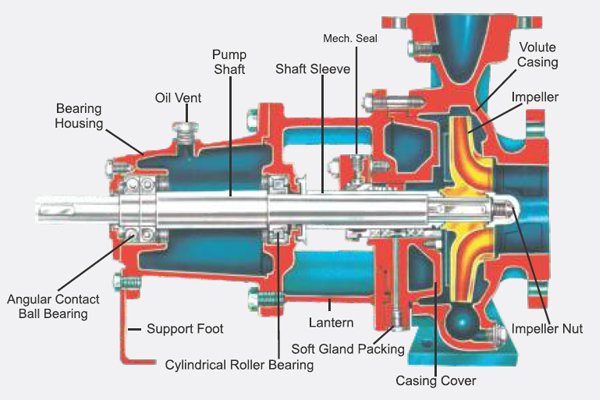

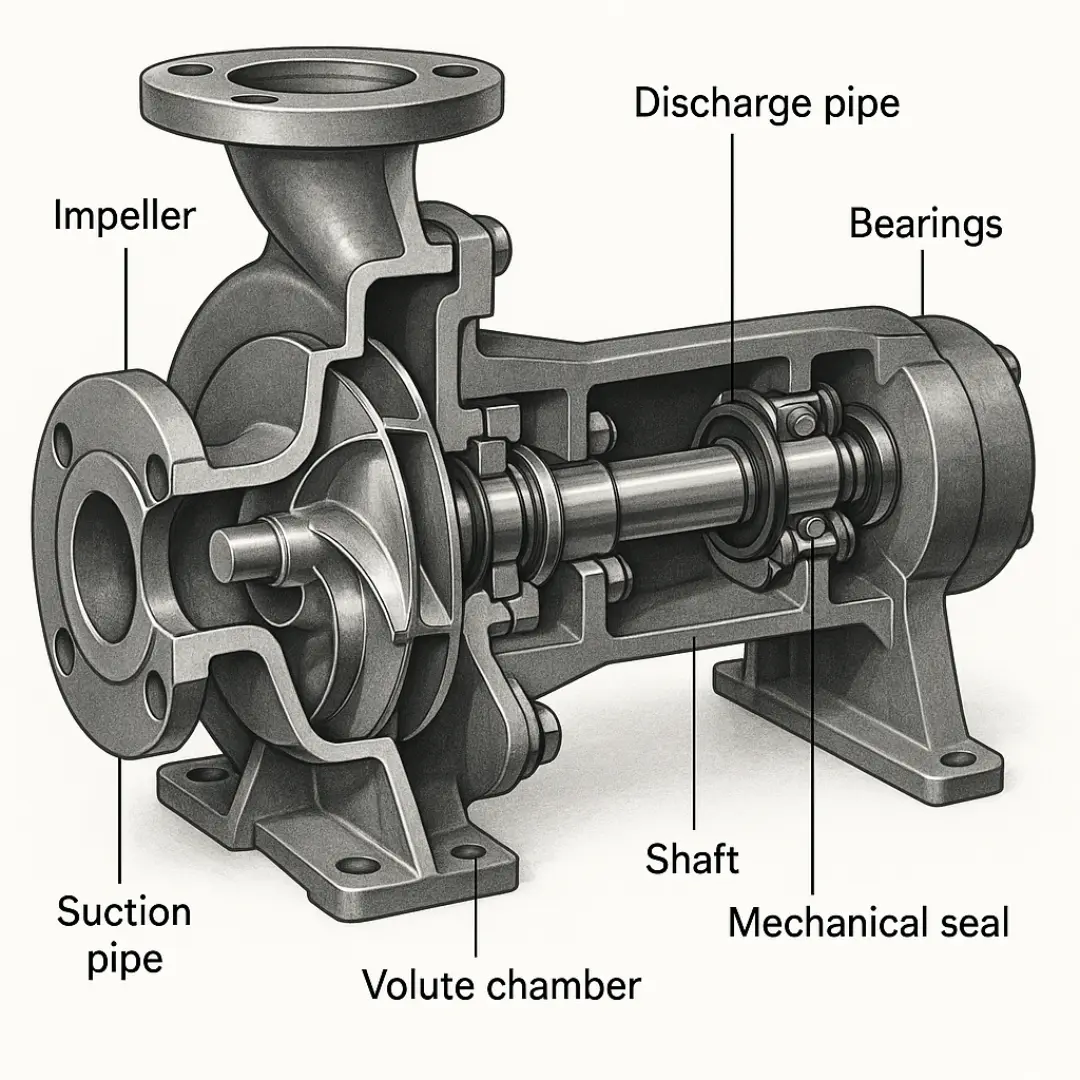

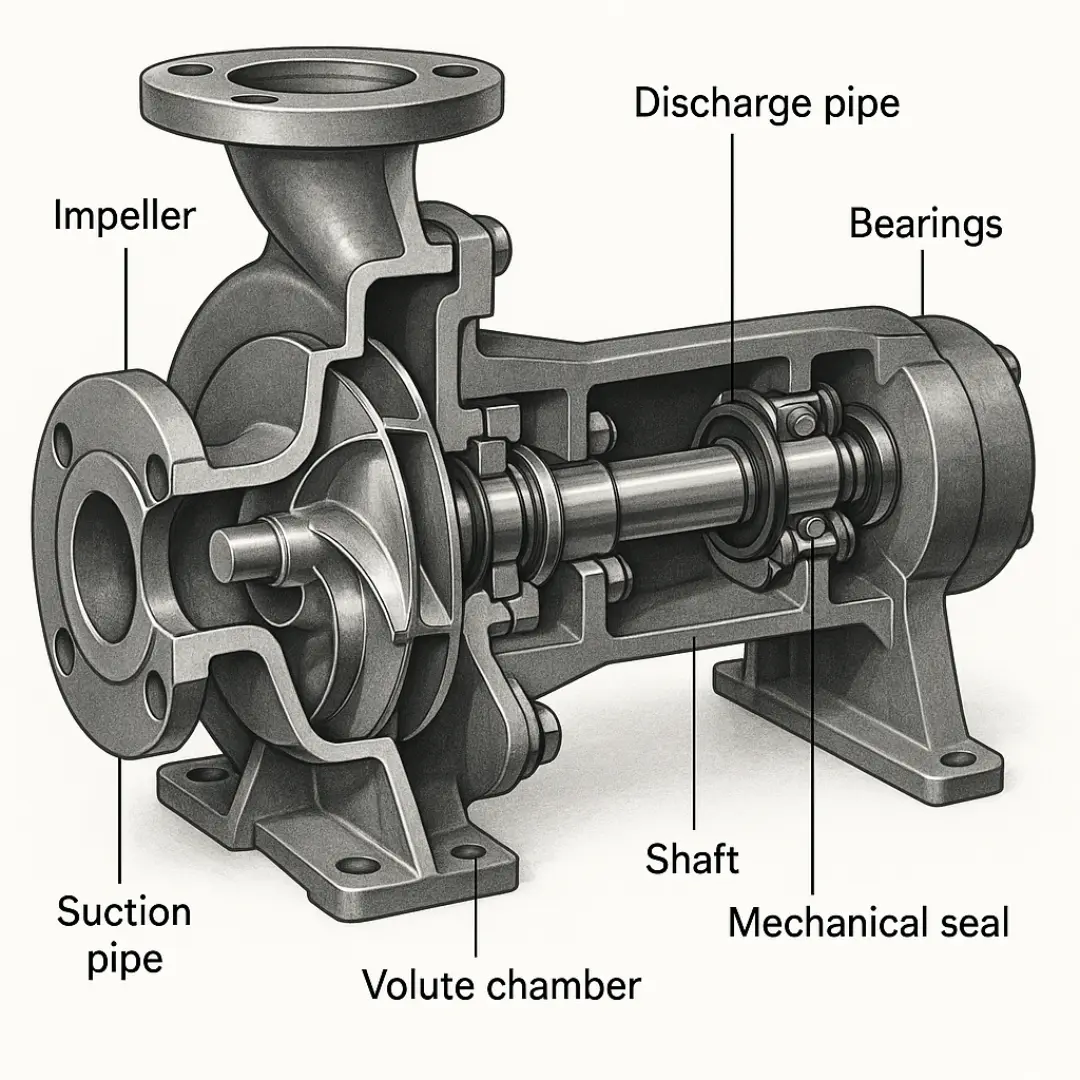

Centrifugal Pump Cross Sectional Drawing & Design

Centrifugal Pump Cross Sectional Drawing & Design

Technical Specifications of Our Industrial Centrifugal Pumps

Materials of Construction for Chemical Resistance

Applications of Centrifugal Pumps

Chemical Industry

Textile Industry

Pharmaceutical Industry

Food & Beverage Industry

Automobile Industry

Sea Water

Agricultural Industry

Oil & Gas Industry

Sugar Plants

Refineries

Marine Applications

Water Supply

Thermic Fluid Boiler

Ceramic Industry

Dyes & Intermediates

Fertilizer Plants

Hot Water Circulation

Cooling Towers

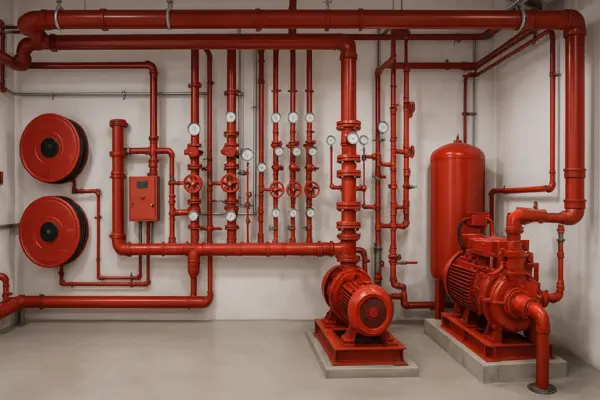

Fire Fighting Systems

Power & Steel Industries

Heat Exchanger

Volatile Liquid Handling

Boiler Feed Water

Irrigation Systems

Dewatering Operations

Laminate Industry

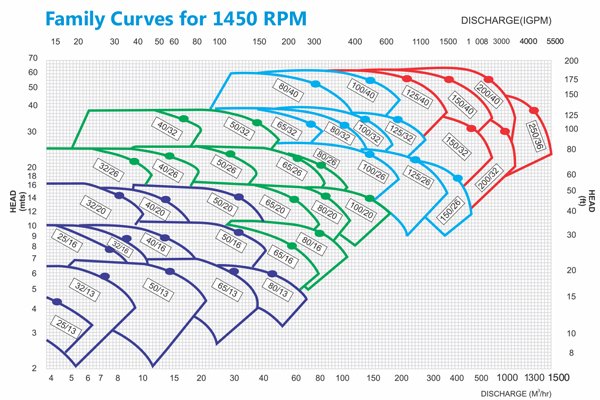

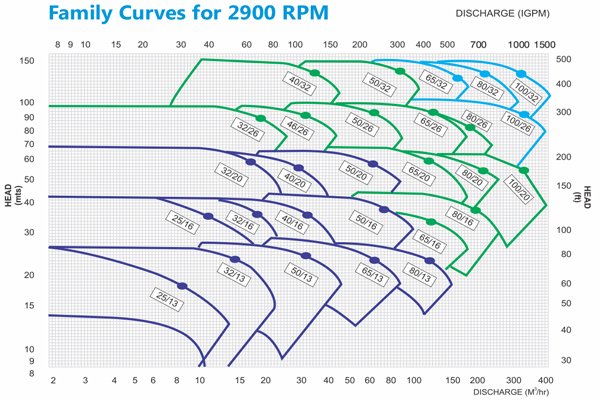

Centrifugal Pump Selection Guide

Benefits of Our High-Efficiency Centrifugal Pumps

- Energy Savings: Advanced impeller design optimizes flow patterns and reduces power requirements while maintaining peak performance.

- Extended Operation: Precision-engineered components and quality materials ensure continuous running with minimal service interruptions.

- Quick Setup: Standardized flanges and compact footprint enable fast installation and seamless integration into existing systems.

- Multi-Industry Use: Capable of handling various liquid types from water to chemicals, suitable for diverse industrial applications.

- Low Service Needs: Self-lubricating design and corrosion-resistant materials reduce maintenance frequency and associated costs.

- Proven Durability: Superior manufacturing standards and rigorous testing guarantee reliable operation for extended periods.

- Energy Savings: Advanced impeller design optimizes flow patterns and reduces power requirements while maintaining peak performance.

- Extended Operation: Precision-engineered components and quality materials ensure continuous running with minimal service interruptions.

- Quick Setup: Standardized flanges and compact footprint enable fast installation and seamless integration into existing systems.

- Multi-Industry Use: Capable of handling various liquid types from water to chemicals, suitable for diverse industrial applications.

- Low Service Needs: Self-lubricating design and corrosion-resistant materials reduce maintenance frequency and associated costs.

- Proven Durability: Superior manufacturing standards and rigorous testing guarantee reliable operation for extended periods.

Customization Options in Industrial Centrifugal Pumps

Centrifugal Pump Installation Guidelines

1. Base Preparation

2. Drive Coupling Alignment

3. Inlet Piping Configuration

4. Outlet Line Support

5. Valve Positioning

Latest Centrifugal Pump Blogs & Technical Articles

Customer Testimonials & Success Stories

Need Help Choosing the Right Centrifugal Pump? Our Experts Are Ready to Assist You

Need Help Choosing the Right Centrifugal Pump? Our Experts Are Ready to Assist You

Frequently Asked Questions – Centrifugal Pumps

Q1: What is the difference between centrifugal and positive displacement pumps?

Centrifugal pumps use rotational energy to move fluids through centrifugal force, while positive displacement pumps trap and force fluid through chambers. Centrifugal pumps are ideal for high flow, low viscosity applications.

Q2: How do I select the right centrifugal pump for my application?

Consider factors like flow rate, head pressure, fluid properties, temperature, and installation space. Our technical team at MRP Pumps can help you choose the optimal pump configuration for your specific needs.

Q3: What maintenance is required for centrifugal pumps?

Regular inspection of seals, bearings, and impeller wear, along with periodic lubrication and alignment checks. MRP pumps are designed for minimal maintenance with self-lubricating components and robust construction.

Q4: Can centrifugal pumps handle viscous fluids?

Centrifugal pumps work best with low to medium viscosity fluids. For highly viscous applications, we recommend our positive displacement pump alternatives for better efficiency.

Q5: What causes cavitation in centrifugal pumps and how to prevent it?

Cavitation occurs when suction pressure drops below fluid vapor pressure, creating bubbles that damage the impeller. Ensure adequate suction head, proper pipe sizing, and avoid excessive suction lift.

Q6: How long do MRP centrifugal pumps typically last?

With proper installation and maintenance, our centrifugal pumps can operate reliably for 15-20 years. Service life depends on application conditions, fluid properties, and maintenance practices.

Q7: What industries commonly use centrifugal pumps?

Water treatment, chemical processing, oil & gas, food & beverage, HVAC systems, and general manufacturing industries rely on centrifugal pumps for their fluid handling requirements.