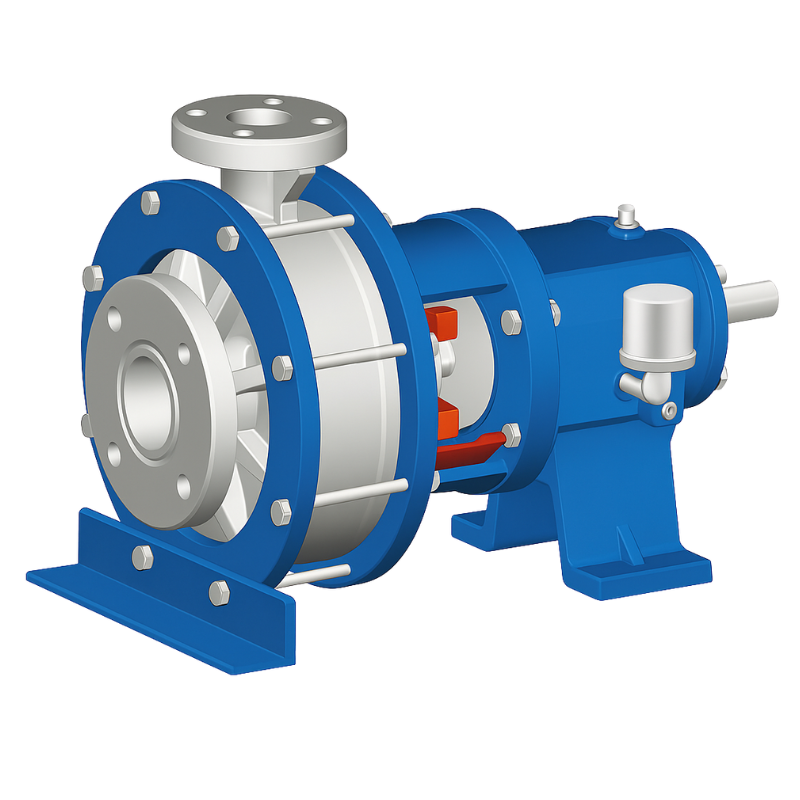

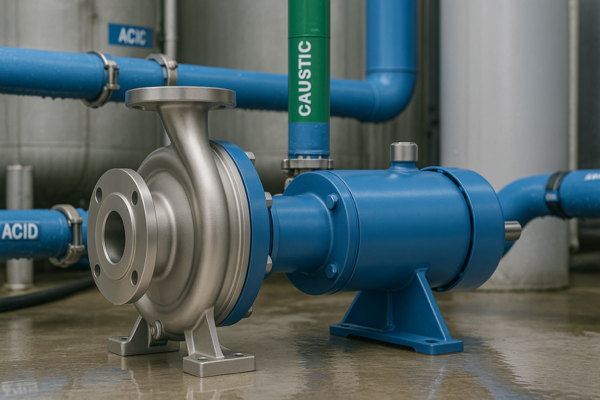

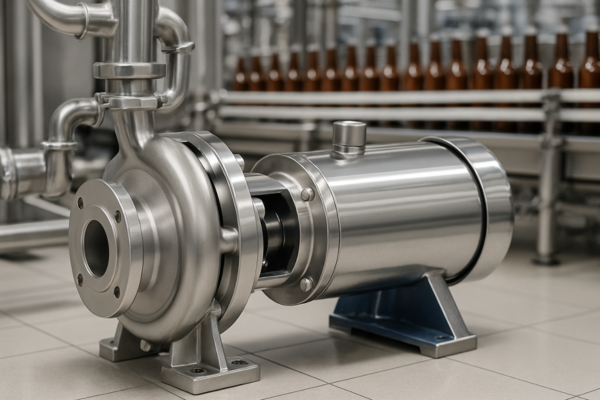

Our Polypropylene Corrosion Resistant Centrifugal Pumps are designed for industries dealing with corrosive and aggressive chemicals. They are perfect for transferring acids, alkalis, and other harsh liquids while easily managing standard pressure and temperature levels. Made from premium polypropylene, these pumps are durable, need minimal maintenance, and are built for continuous operation, reducing downtime and improving efficiency.

Easy to install and maintain, they feature a smart design with corrosion-resistant seals for reliable, long-lasting performance. Widely used in chemical processing, electroplating, pharmaceuticals, and water treatment, these pumps provide energy-efficient operation and flexible installation options, making them a safe, dependable, and cost-effective solution for handling corrosive fluids in multiple industrial applications.

Order Your Polypropylene Corrosion Resistant Centrifugal Pump – Built for Harsh Chemicals

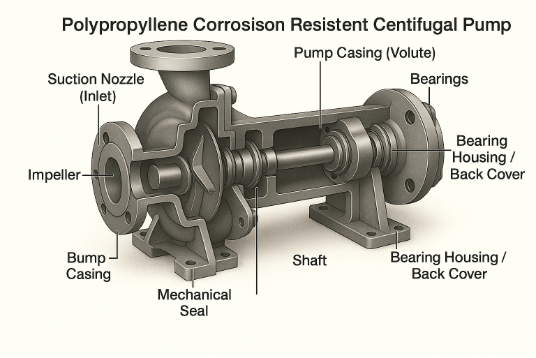

Polypropylene Corrosion Resistant Centrifugal Pump Cross Sectional Drawing & Design

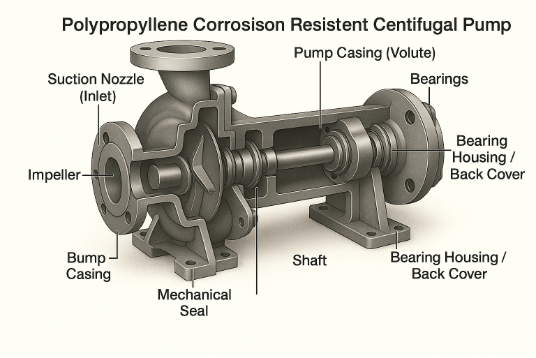

Polypropylene Corrosion Resistant Centrifugal Pump Cross Sectional Drawing & Design

Technical Specifications of Polypropylene Corrosion Resistant Centrifugal Pump

Materials of Construction for Chemical Resistance

Download Our Polypropylene Corrosion Resistant Centrifugal Pump Catalogue

Applications of Polypropylene Corrosion Resistant Centrifugal Pump

Textile Industry

Electroplating

Dyes & Pigments

Effluent Treatment

Pickling Lines

Gas Scrubbing

Sugar Industry

Paper Industry

Steel Plants

Acid Handling

Food Processing

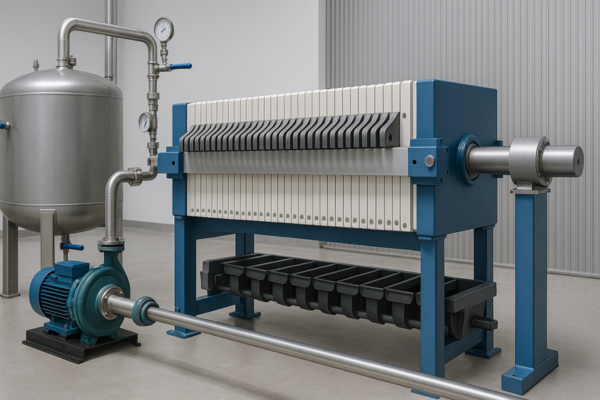

Filter Press

Water Treatment

Chemical Transfer

Alkali Handling

Polypropylene Corrosion Resistant Centrifugal Pump Selection Guide

Benefits of Our High-Efficiency Polypropylene Corrosion Resistant Centrifugal Pump

- Strong Chemical Resistance: Polypropylene construction ensures safe transfer of aggressive chemicals and corrosive liquids without damage.

- Lower Operating Costs: Efficient hydraulic design minimizes energy use and helps reduce long-term operating expenses.

- Minimal Downtime: The durable build supports continuous service with fewer failures and less frequent repairs.

- Easy Installation: Compact horizontal design with standard inlet/outlet connections simplifies system integration.

- Low Maintenance: Reliable seals and corrosion-resistant parts reduce maintenance frequency and service costs.

- Long Service Life: High-quality polypropylene materials ensure dependable performance and extended pump life.

- Strong Chemical Resistance: Polypropylene construction ensures safe transfer of aggressive chemicals and corrosive liquids without damage.

- Lower Operating Costs: Efficient hydraulic design minimizes energy use and helps reduce long-term operating expenses.

- Minimal Downtime: The durable build supports continuous service with fewer failures and less frequent repairs.

- Easy Installation: Compact horizontal design with standard inlet/outlet connections simplifies system integration.

- Low Maintenance: Reliable seals and corrosion-resistant parts reduce maintenance frequency and service costs.

- Long Service Life: High-quality polypropylene materials ensure dependable performance and extended pump life.

Customization Options in Industrial Polypropylene Corrosion Resistant Centrifugal Pump

Polypropylene Corrosion Resistant Centrifugal Pump Installation Guidelines

1. Prepare a Strong Base

2. Align Pump and Motor

3. Set Up Suction Piping

4. Support Discharge Piping

5. Install Valves Properly

Latest Polypropylene Corrosion Resistant Centrifugal Pump Blogs & Technical Articles

Customer Testimonials & Success Stories

Contact Our Centrifugal End Suction Pump Experts

Contact Our Polypropylene Corrosion Resistant Centrifugal Pump Experts

Frequently Asked Questions – Polypropylene Corrosion Resistant Centrifugal Pump

Q1: What is a polypropylene corrosion resistant centrifugal pump used for?

It is used for safely transferring corrosive chemicals, acids, alkalis, and aggressive fluids in industrial applications.

Q2: Why choose a polypropylene centrifugal pump over metal pumps?

Polypropylene pumps resist corrosion better than metal pumps, making them ideal for handling strong chemicals.

Q3: Can polypropylene centrifugal pumps handle high temperatures?

Yes, they can handle temperatures up to 140°C, depending on the application and design.

Q4: Which industries use polypropylene corrosion resistant pumps?

They are widely used in chemical processing, electroplating, pharmaceuticals, water treatment, and steel plants.

Q5: What chemicals can a polypropylene centrifugal pump handle?

They can handle HCL, sulphuric acid, caustic soda, alkalis, solvents, and other corrosive liquids.

Q6: How long do polypropylene centrifugal pumps last?

With proper installation and maintenance, these pumps provide long-term, reliable service in harsh environments.

Q7: How do I select the right polypropylene centrifugal pump?

Consider flow rate, head pressure, chemical compatibility, temperature, and operating conditions for proper sizing.