Centrifugal End Suction Pump Manufacturer

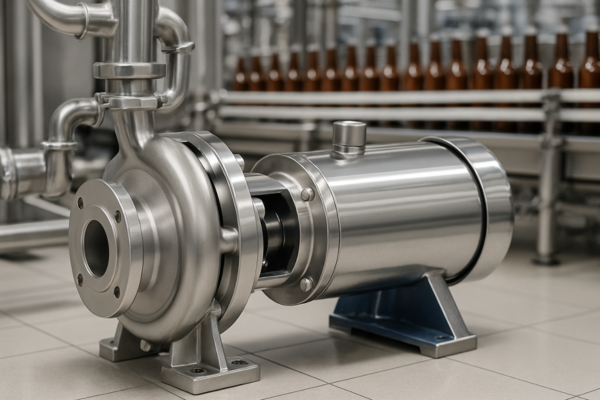

Our centrifugal end suction pumps are made to work reliably and efficiently in many different industries. They are great for moving clean or slightly dirty liquids and can handle normal levels of pressure and heat. Made with strong materials, these pumps last longer and need no more repairs. They are built to run continuously, helping your operations run smoothly with less downtime.

These pumps are easy to install and simple to take care of. Their smart design and strong seals help them work well for a long time. They are used in areas like water treatment, cooling systems, textile units, and general factories. With flexible installation options and energy-saving features, these pumps are a smart and affordable choice for many types of industrial needs.

Get Reliable Centrifugal End Suction Pumps – Fast & Customized

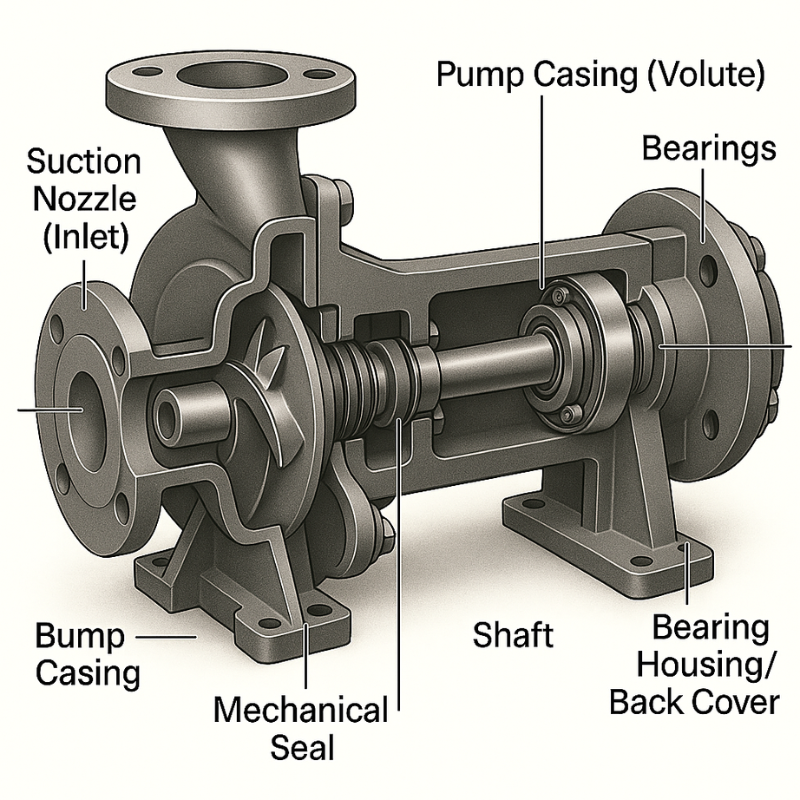

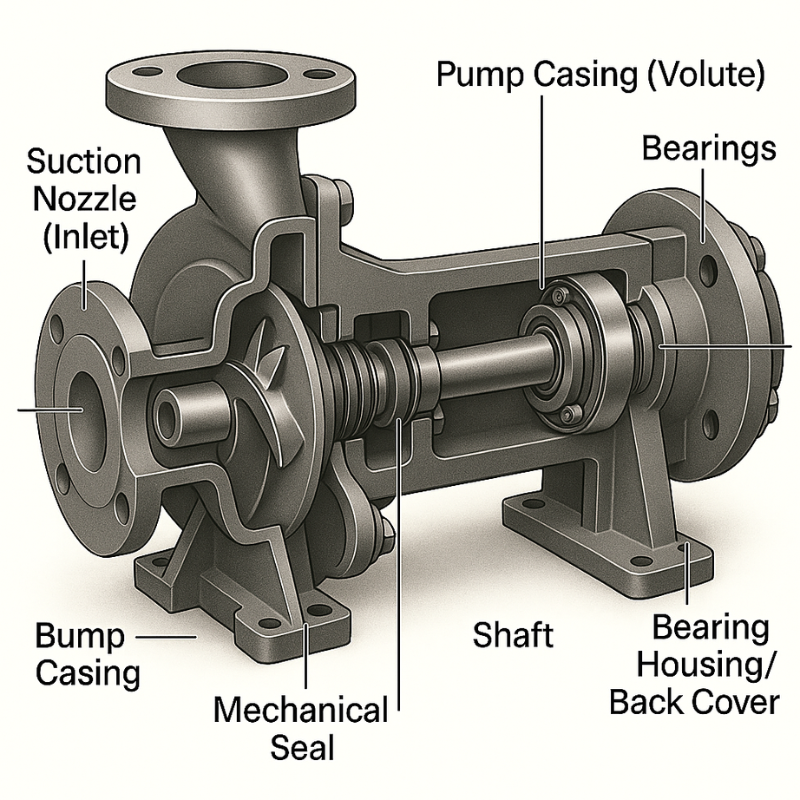

Centrifugal End Suction Pump Cross Sectional Drawing & Design

Centrifugal End Suction Pump Cross Sectional Drawing & Design

Technical Specifications of Centrifugal End Suction Pump

Materials of Construction for Chemical Resistance

Download Our Centrifugal End Suction Pump Catalogue

Applications of Centrifugal End Suction Pumps

Textiles

Jet Dyeing

Effluent Treatment Plants

Oil Extraction

Waste Management

Sugar, Salt & Starch Plants

Hot & Cold-Water Circulation

Pulp & Paper Industries

Cement & Steel Plants

Bulk Drugs & Pharmaceutical

HVAC & Utility Systems

Organic & Inorganic Liquid Handling

Food & Beverage Industries

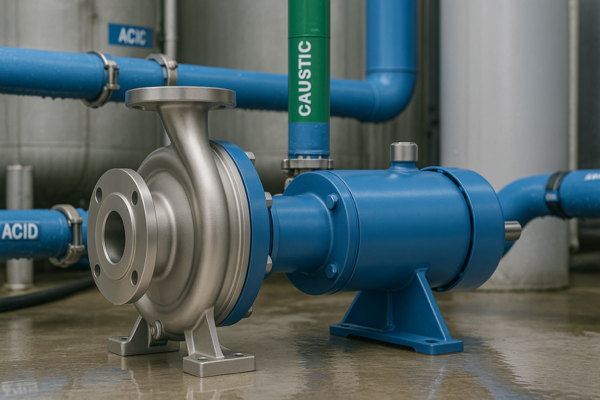

Caustic & Acidic Liquid Transfer

Industrial Cleaning & Washing Systems

Slurry Transfer

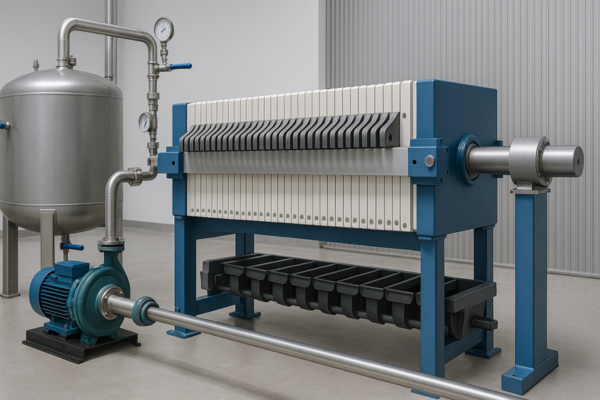

Filter Press Feeding

Centrifugal End Suction Pump Selection Guide

Benefits of Our High-Efficiency Centrifugal End Suction Pumps

- Lower Operating Costs: Efficient hydraulic design helps reduce energy use and operating expenses over time.

- Minimal Downtime: Durable build supports continuous operation with less failures and maintenance needs.

- Easy Installation: Space-saving horizontal design with standard inlet/outlet simplifies setup in existing systems.

- Reduced Maintenance: Reliable sealing and bearing systems lower maintenance frequency and service costs.

- Versatile Applications: Suitable for clean and slightly polluted fluids across various industrial and utility uses.

- Long Service Life: High-quality materials and strong construction provide dependable, long-term performance.

- Lower Operating Costs: Efficient hydraulic design helps reduce energy use and operating expenses over time.

- Minimal Downtime: Durable build supports continuous operation with less failures and maintenance needs.

- Easy Installation: Space-saving horizontal design with standard inlet/outlet simplifies setup in existing systems.

- Reduced Maintenance: Reliable sealing and bearing systems lower maintenance frequency and service costs.

- Versatile Applications: Suitable for clean and slightly polluted fluids across various industrial and utility uses.

- Long Service Life: High-quality materials and strong construction provide dependable, long-term performance.

Customization Options in Industrial Centrifugal End Suction Pumps

Centrifugal End Suction Pump Installation Guidelines

1. Foundation Preparation

2. Pump-Motor Alignment

3. Suction Line Setup

4. Discharge Piping Support

5. Control Valve Installation

Latest Centrifugal End Suction Pump Blogs & Technical Articles

Customer Testimonials & Success Stories

Contact Our Centrifugal End Suction Pump Experts

Contact Our Centrifugal End Suction Pump Experts

Frequently Asked Questions – Centrifugal End Suction Pumps

Q1: What is a centrifugal end suction pump?

It’s a single-stage centrifugal pump where fluid enters the end (suction) and exits through the top or side. It uses a rotating impeller to generate centrifugal force and move liquids efficiently.

Q2: Where are end suction pumps typically used?

Commonly found in water supply, HVAC, firefighting, irrigation, wastewater treatment, and light-duty chemical services.

Q3: How do I select the right end suction pump for my application?

Key factors include flow rate, head, fluid properties (viscosity, temperature, compatibility), material selection, efficiency, NPSH requirements, and system layout.

Q4: What materials are used in end suction pump construction?

Typical materials include cast iron, bronze, stainless steel (SS‑304/SS‑316), duplex and super-duplex stainless steels, and corrosion-resistant alloys like Hastelloy and Alloy 20.

Q5: What are the main advantages and disadvantages of the end suction pump?

Advantages: Compact design, easy maintenance, cost-effective, energy efficient.

Disadvantages: Limited head capacity, potential cavitation, requires priming, less suitable for viscous & abrasive fluids.

Q6: How do you prevent clogging in end suction pumps?

Ensure Net Positive Suction Head Available (NPSHa) exceeds NPSH required, use proper pipe sizing, reduce suction lift, and consider a greater or smaller elbow radius on the suction side.

Q7: What are common maintenance issues and fixes?

Issues include cavitation, vibration, seal and bearing wear, and impeller clogging. Solutions involve proper installation (alignment, foundation), routine inspections, lubrication, seal replacement, and cleaning suction strainers.