Air Cooled Pump Manufacturer in India

MRP Pumps & Seals is a leading air-cooled pump manufacturer in India, based in Kathwada, Ahmedabad. With over 15 years of experience, we manufacture high-performance air-cooled pumps for demanding high-temperature industrial applications.

Our air-cooled pumps handle hot process fluids, thermal oils, and high-temperature liquids efficiently. Built with advanced canned motor technology and air-cooling systems, these pumps ensure reliable operation in the chemical, petrochemical, thermal processing, and power generation industries.

Featuring robust construction, energy-efficient design, and minimal maintenance requirements, our pumps deliver consistent performance under extreme temperature conditions. Easy installation and modular design reduce downtime and operational costs, making them ideal for continuous high-temperature industrial processes.

Contact Mrp Pumps for Expert Help Choosing the Right Air-cooled Pump for Your High-temperature Application.

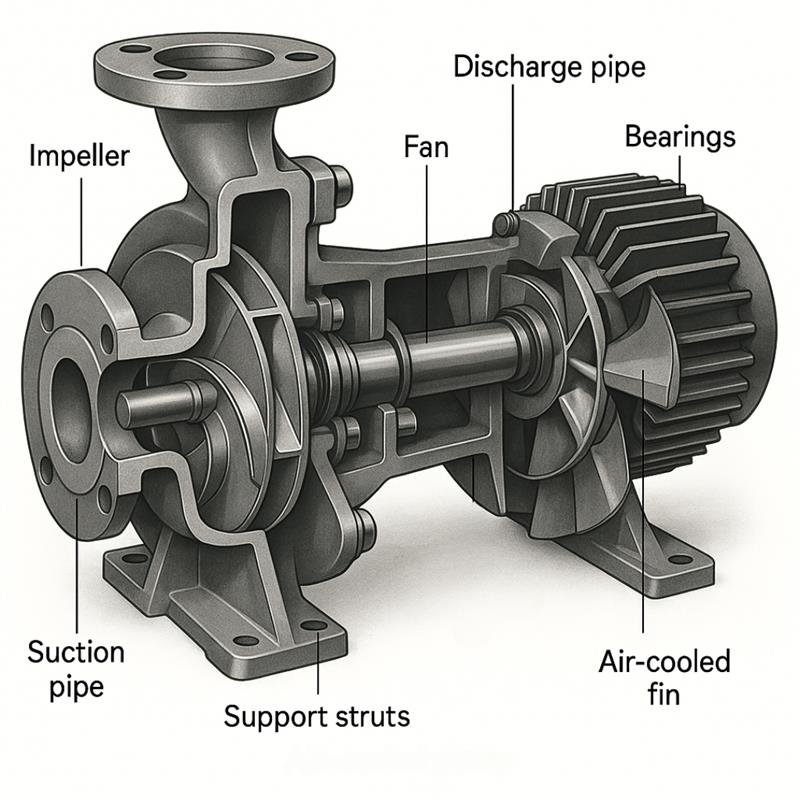

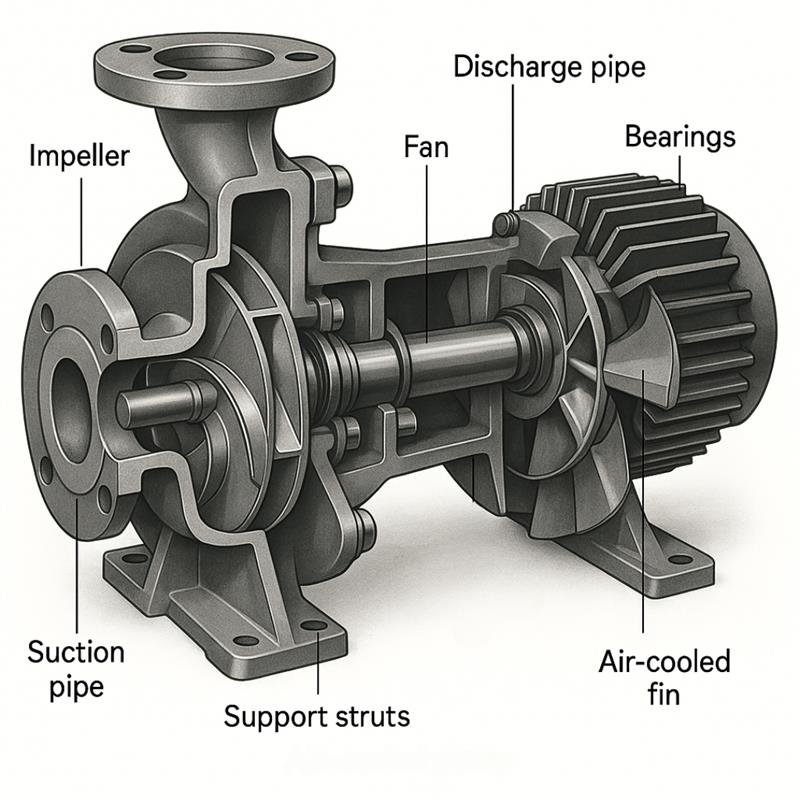

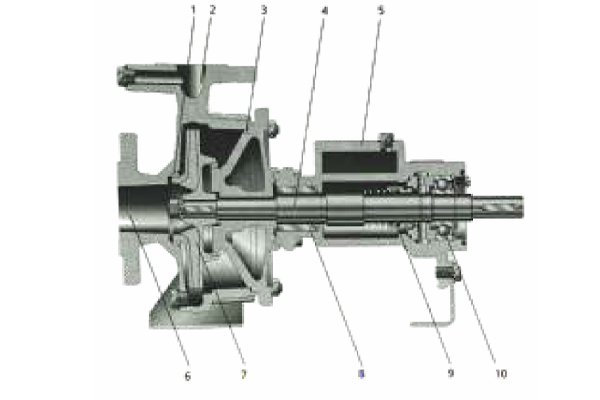

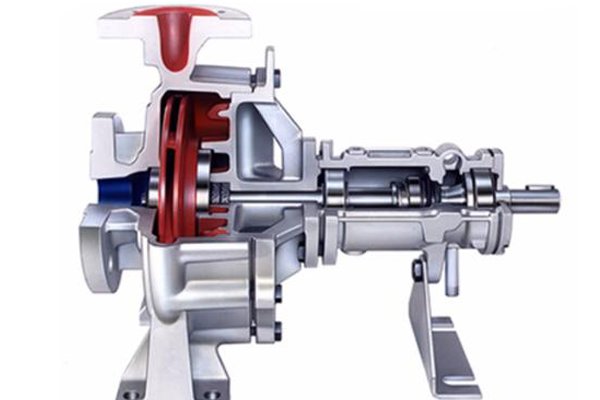

Air Cooled Pump Cross Sectional Drawing & Design

Air Cooled Pump Cross Sectional Drawing & Design

Technical Specifications of Industrial Air-Cooled Pumps

Materials of Construction for High Temperature Applications

Download Our Air-Cooled Pumps Catalogue

Applications of Air-Cooled Pumps

Textile Industry

Chemical Processing

Plastic Industry

Paper Industry

Sugar Industries

Edible Oil Applications

Food And Drug Industry

Pharmaceutical Industries

Thermal Oil Systems

Hot Water Distribution

Solar Thermal Plants

Geothermal Applications

Industrial Furnaces

Petrochemical Refineries

Mineral Oil Industry

Power Generation Plants

Steel Manufacturing

Air Cooled Pump Selection Guide

Benefits of Our High-Efficiency Air Cooled Pumps

- Reduced Energy Consumption: Optimized thermal design decreases power requirements and lowers electricity costs effectively.

- Enhanced Uptime: Durable construction guarantees continuous operation with reduced failures and maintenance needs.

- Simplified Installation: Space-saving design and universal connections facilitate installation in current systems.

- Extended Maintenance Intervals: Self-contained cooling technology and durable components prolong service periods significantly.

- Multi-Purpose Applications: Processes various hot fluids from thermal oils to high-temperature process liquids across multiple industries.

- Extended Equipment Life: Superior materials and engineering precision ensure years of dependable high-temperature operation.

- Reduced Energy Consumption: Optimized thermal design decreases power requirements and lowers electricity costs effectively.

- Enhanced Uptime: Durable construction guarantees continuous operation with reduced failures and maintenance needs.

- Simplified Installation: Space-saving design and universal connections facilitate installation in current systems.

- Extended Maintenance Intervals: Self-contained cooling technology and durable components prolong service periods significantly.

- Multi-Purpose Applications: Processes various hot fluids from thermal oils to high-temperature process liquids across multiple industries.

- Extended Equipment Life: Superior materials and engineering precision ensure years of dependable high-temperature operation.

Customization Options in Industrial Air-Cooled Pumps

Air Cooled Pump Installation Guidelines

1. Foundation Preparation

2. Pump-Motor Alignment

3. Suction Line Setup

4. Discharge Piping Support

5. Cooling Air Flow

Customer Testimonials & Success Stories

Latest Air-Cooled Pump Blogs & Technical Articles

Frequently Asked Questions – Air Cooled Pumps

Q1: What is the price of air-cooled pumps in India?

MRP Pumps offers competitive pricing for air cooled pumps. Contact us for detailed quotations based on your high-temperature specifications.

Q2: Which is the best air-cooled pump manufacturer in Ahmedabad?

MRP Pumps is a leading air-cooled pump manufacturer in Ahmedabad with 15+ years of experience and proven high-temperature industry expertise.

Q3: How to select the right air-cooled pump for high-temperature applications?

Consider flow rate, head pressure, fluid temperature, thermal properties, and material compatibility. Our experts provide free consultations.

Q4: What is the difference between air cooled and water-cooled pumps?

Air cooled pumps use ambient air for cooling, eliminating water quality concerns, while water cooled pumps require continuous cooling water supply.

Q5: How long do industrial air-cooled pumps last?

MRP air cooled pumps typically last 10-15 years with proper maintenance in industrial high-temperature processing applications.

Q6: What maintenance is required for air cooled pumps?

Regular bearing lubrication, cooling system inspection, impeller cleaning, and thermal expansion checks ensure optimal pump performance and longevity.

Q7: Can air cooled pumps handle extreme high temperatures?

Yes, MRP pumps are designed for temperatures up to 350°C using specialized materials and advanced air-cooling technology for high-temperature applications.