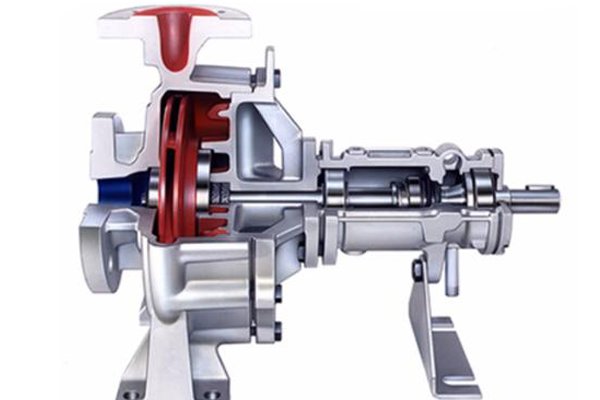

Air-cooled canned motor pumps designed for hightemperature applications isolate liquid in the motor section of the unit for the hot process fluid in the pump casing with a series of pressure ports located in the front bearing housing or pump casing adapter. This isolated liquid (usually the same fluid as the pumped fluid) is circulated through an air-cooled heat exchanger by an auxiliary impeller located on the rotor assembly.

This design allows the motor and bearing environment to be at a much lower temperature than the process fluid, enabling the use of standard bearings and motor insulation significantly reducing both first and long term operating and maintenance costs and eliminates the need for cooling water that could be of poor quality.

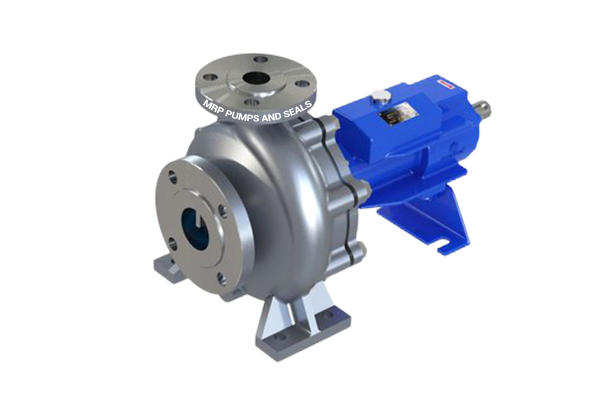

Model : AMRP / KMRP

ADVANTAGES

- Standard Motor Insulation Á Bearings.

- Bearing Environment At Lower Temperatures.

- Secondary Containment.

- Eliminates The Consern of Fouling Caused By Poor Water Quality.

- Bearing Wear Monitors Available.

OPERATING RANGE

- Capacity -Q- : up to 300 m3/hr

- Head : up to 150 MLC

- Pump Size – DN : 25 mm to 300 mm

- Speed -N- : 1450/2900 rpm at 50 Hz & 3500 rpm at 60 Hz

- Temperature : up to +350℃ max.

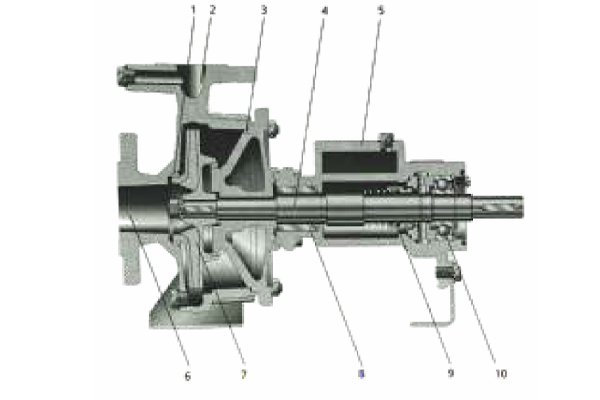

SECTIONAL DRAWING

- Clearance Gap

- Discharge Nozzle

- Casing Cover

- Shaft

- Bearing Bracket

- Suction Nozzle

- Impeller

- Plain Bearing

- Shaft Seal

- Motor End, Rolling Element Bearing